-

Nondestructive test (filter remains usable after testing)

-

Rapid, reliable, and repeatable

-

Detects oversized pores or defects in membranes

-

Correlates with filter pore size and retention rating

-

Widely accepted in regulatory guidelines (FDA, EMA, WHO, ISO)

-

Suitable for in-line or offline validation setups

-

Filter Types: Hydrophilic and hydrophobic membranes (with pre-wetting for hydrophobic)

-

Configurations: Single cartridge, capsule filters, disc filters

-

Liquids for Wetting: Water, isopropanol-water mixture (for hydrophobic membranes)

-

Test Equipment: Manual integrity testers, automated digital integrity testers

-

Documentation: 21 CFR Part 11 compliant electronic records (for pharma validation)

-

Typical Test Pressure Range: 200 mbar to 7 bar (depending on filter rating)

-

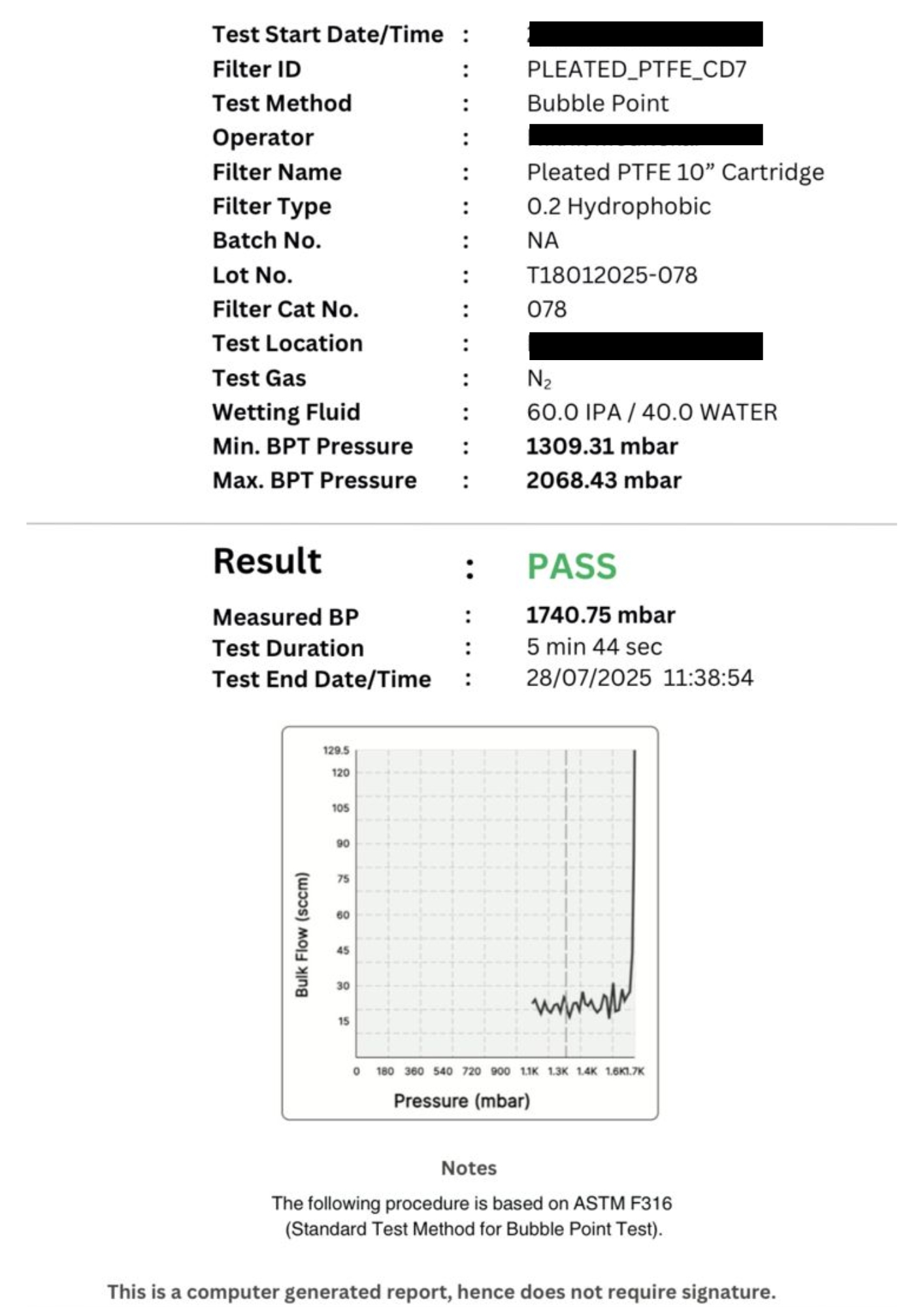

Filter Pore Size Correlation:

-

0.1 µm → ~3.5 bar

-

0.2 µm → ~2.4 bar

-

0.45 µm → ~1.0 bar

-

0.65 µm → ~0.6 bar

-

-

Gas Used: Compressed air or nitrogen

-

Accuracy: ±2% of full scale (automated systems)

-

Compliance: ASTM F316, PDA TR26, ISO 29463, EN 1822, GMP Annex 1

-

Sterile filtration validation in pharma manufacturing

-

Biotech fermentation media and buffer filtration

-

Water-for-Injection (WFI) and purified water systems

-

Final filtration in food & beverage (beer, wine, soft drinks)

-

Microelectronics ultrapure water systems

-

Medical device manufacturing sterility assurance